Process Improvement in Volume Resistivity Detection of Semi-Conductive Shield for Large-Scale Cables

Introduction

The volume resistivity of semi-conductive shields plays a crucial role in determining the electrical performance of high-voltage cables. These shields help regulate electric field distribution, reduce partial discharge, and enhance insulation stability. However, traditional detection methods for large-scale cables suffer from several challenges:

✔ Manual sample preparation results in uneven surfaces, leading to inconsistent test data.

✔ Low testing efficiency makes large-scale quality control difficult.

✔ Current resistivity measurement techniques lack precision, particularly for high-resistance samples.

This study proposes an improved testing process using large-scale cutting machines, fixed mold techniques, and copper sheet molds to enhance the accuracy and reliability of volume resistivity detection for semi-conductive shields in large-diameter cables (64/110 kV and above).

1. Key Challenges in Current Testing Methods

1.1 Sample Preparation Issues

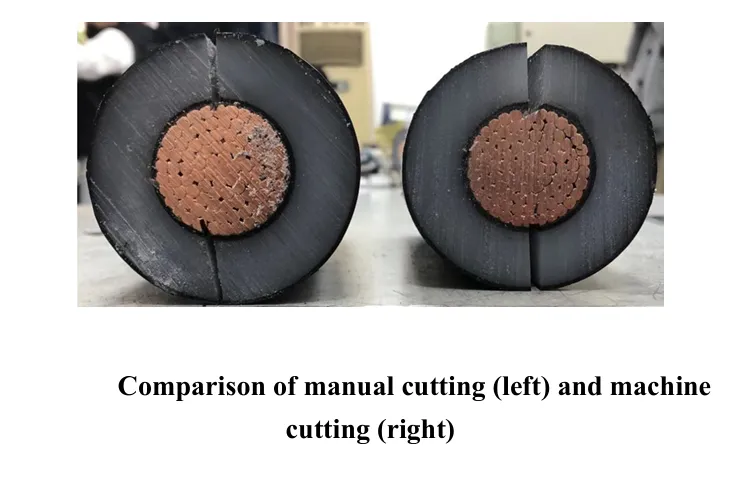

Large-diameter cables require precise sample preparation, but manual cutting methods introduce several problems:

- Irregular sample surfaces → Affects contact between electrodes and sample.

- Low efficiency → Time-consuming manual operations slow down testing.

- High rejection rates → Errors in cutting lead to wasted samples.

| Factor | Manual Cutting | Large-Scale Cutting Machine |

|---|---|---|

| Surface Quality | Rough, uneven | Smooth, precise |

| Cutting Time | Long (5–10 min per sample) | Short (1–2 min per sample) |

| Safety | Risk of hand injuries | Controlled cutting process |

➡ Conclusion: Upgrading to large-scale cutting machines significantly improves efficiency and safety.

1.2 Problems in Volume Resistivity Measurement

A. Conductor Shield Resistivity Testing Issues

Traditional conductive paste coating method for resistivity testing suffers from:

- Long curing times (12+ hours at room temperature).

- Electrode damage due to sharp contact points.

B. Insulation Shield Resistivity Testing Issues

The self-adhesive copper tape method, commonly used for insulation shields, has drawbacks:

- Weak adhesion at high temperatures (90°C) → Copper tape falls off.

- Uneven contact with the sample, causing measurement errors.

➡ Conclusion: A more stable and repeatable resistivity testing process is needed.

2. Proposed Process Improvements

2.1 Upgraded Sample Preparation Method

Large-scale cutting machines were introduced to replace manual cutting, ensuring smooth, uniform sample surfaces.

➡ Effect: Increased efficiency, improved cutting accuracy, and reduced sample waste.

2.2 Improved Volume Resistivity Testing Techniques

A. Copper Sheet Mold Method (Replacing Conductive Paste Method)

✔ Pre-fabricated copper sheet molds ensure stable contact with the sample.

✔ Eliminates long curing times, improving testing speed.

B. Fixed Mold Method (Replacing Self-Adhesive Copper Tape Method)

✔ Uses a tight-fit mold to secure copper electrodes against the sample.

✔ Prevents detachment at high temperatures, ensuring reliable data collection.

| Method | Advantages | Replaced Method |

|---|---|---|

| Copper Sheet Mold | Fast, repeatable, high accuracy | Conductive paste method |

| Fixed Mold | No adhesive issues, stable contact | Self-adhesive copper tape |

➡ Effect: Enhanced measurement consistency, reducing error rates.

3. Experimental Validation and Results

3.1 Sample Quality Comparison

| Cutting Method | Surface Smoothness | Preparation Time |

|---|---|---|

| Manual Cutting | Uneven | ~10 min/sample |

| Large-Scale Cutting | Smooth | ~2 min/sample |

➡ Key Finding: Automated cutting ensures smoother samples and faster preparation.

3.2 Volume Resistivity Test Results

Tested on 64/110 kV cables with different cross-sectional areas:

A. Conductor Shield Resistivity Results

| Method | Volume Resistivity (Ω·m) after Heating |

|---|---|

| Conductive Paste | 6.62 (0.5h) → 5.90 (1.5h) |

| Copper Sheet Mold | 5.91 (0.5h) → 5.66 (1.5h) |

➡ Copper sheet method consistently produced lower and more stable resistance values.

B. Insulation Shield Resistivity Results

| Method | Volume Resistivity (Ω·m) after Heating |

|---|---|

| Self-Adhesive Copper Tape | 5.69 (0.5h) → 1.82 (1.5h) |

| Fixed Mold | 1.71 (0.5h) → 1.69 (1.5h) |

➡ Fixed mold method significantly reduced resistance fluctuations, ensuring measurement accuracy.

4. Engineering Insights and Industry Implications

4.1 Impact on Quality Control

✔ Higher repeatability → Eliminates sample variation.

✔ Reduced testing time → Increases productivity in manufacturing QC labs.

4.2 Economic and Industrial Benefits

| Aspect | Improvement |

|---|---|

| Production Efficiency | +30% faster testing cycle |

| Testing Cost | -20% material waste reduction |

| Compliance with Standards | Meets GB/T 11017.1-2014 requirements |

➡ Manufacturers can improve efficiency while maintaining high-quality standards.

5. Conclusion and Recommendations

5.1 Summary of Key Improvements

✔ Large-scale cutting machines enhance sample preparation efficiency.

✔ Copper sheet molds eliminate inconsistencies in conductor shield resistivity testing.

✔ Fixed mold technique ensures reliable insulation shield resistivity measurement.

5.2 Future Research Directions

- AI-driven automation for real-time defect detection.

- Advanced materials for better shield conductivity and stability.

- Integration with smart monitoring systems for in-line testing.

Final Verdict: These improvements enhance testing accuracy and efficiency, making them highly beneficial for large-scale cable manufacturers.

Keywords

- Large-Scale Cables

- Semi-Conductive Shield

- Volume Resistivity Testing

- High-Voltage Power Cables

- Quality Control in Cable Manufacturing

References

- Li Mei (2025). Process Improvement in Volume Resistivity Detection of Semi-Conductive Shield for Large-Scale Cables. Wire & Cable, 68(1), 55-60. DOI: 10.16105/j.dxdl.1672-6901.20240095

- GB/T 11017.1-2014 – Test Methods for High Voltage Power Cable Shielding

- GB/T 3048.3-2007 – Electrical Performance Testing of Semi-Conductive Materials

Comments

Post a Comment