Difference Between Control Cable and Power Cable

Control cables and power cables serve distinct roles in electrical systems, each designed for specific functions, current capacities, and applications. Understanding their differences is crucial for ensuring safety and efficiency in residential, commercial, or industrial settings. This article explores these differences through three key sections, using a table to compare their characteristics and analogies to make concepts engaging.

Table of Contents

What Are Control Cables and Power Cables?

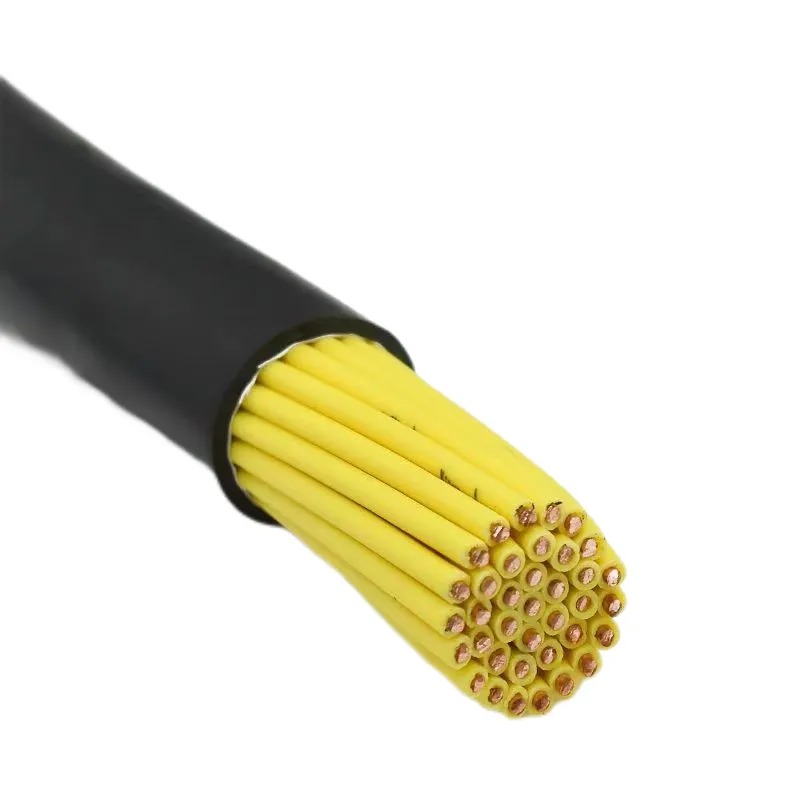

Control Cables are designed to transmit low-voltage signals for controlling, monitoring, or automating equipment. They typically carry currents of a few amps (e.g., 1A to 5A) at voltages below 600V, often 24V to 110V, and are used to send signals to relays, sensors, or motors to manage operations. Control cables usually have multiple conductors (e.g., 2 to 50 cores) to handle various signals simultaneously.

Power Cables are built to transmit electrical power, carrying higher currents and voltages to supply energy to devices, machinery, or entire buildings. They operate at voltages from 120V (household) up to 35 kV (medium voltage) or higher, with currents ranging from 15A to hundreds of amps, depending on the application. Power cables typically have fewer conductors (e.g., 2 to 5) but are thicker to handle the load.

Think of control cables as the nervous system of a building, sending precise signals to control operations, while power cables are the arteries, delivering the raw energy needed to keep everything running.

How Do Control Cables and Power Cables Differ?

Control cables and power cables differ in their design, electrical specifications, and construction to suit their respective purposes. Here’s a detailed comparison:

| Feature | Control Cable | Power Cable |

|---|---|---|

| Purpose | Transmits control signals for automation | Transmits electrical power to devices |

| Voltage Rating | Low voltage (e.g., 24V to 600V) | Low to high voltage (120V to 35 kV+) |

| Current Capacity | Low current (1A to 5A typically) | High current (15A to hundreds of amps) |

| Conductor Count | Multiple conductors (2 to 50+ cores) | Fewer conductors (2 to 5 cores) |

| Conductor Size | Smaller (e.g., 18 AWG to 14 AWG) | Larger (e.g., 14 AWG to 2/0 AWG) |

| Shielding | Often shielded to reduce EMI | Rarely shielded unless high voltage |

| Insulation | Thinner insulation (e.g., PVC) | Thicker insulation (e.g., XLPE, EPR) |

| Flexibility | More flexible for complex routing | Less flexible, designed for fixed runs |

Control cables prioritize signal integrity with shielding and flexibility, while power cables focus on safely carrying high currents with robust insulation. It’s like comparing a bicycle (control cable) to a freight truck (power cable)—one is nimble and precise, the other is built for heavy-duty transport.

Where Are Control Cables and Power Cables Used?

The distinct designs of control and power cables make them suited for different applications across various settings.

- Control Cables: Used in automation systems, such as industrial machinery (e.g., connecting PLCs to motors), HVAC systems (e.g., thermostat wiring), or home automation (e.g., smart lighting controls). For example, a 24V control cable might connect a thermostat to an HVAC unit to regulate temperature.

- Power Cables: Used to supply electricity to devices and systems, such as household wiring (e.g., NM-B for 120V outlets), industrial power distribution (e.g., 11 kV cables for factories), or overhead transmission lines (e.g., ACSR for 230 kV). For instance, a 12 AWG power cable might deliver 20A to a kitchen outlet for a microwave.

Control cables are often found in scenarios requiring precise communication, while power cables dominate where energy delivery is the priority. They complement each other like a conductor and an orchestra—the control cable directs the performance, while the power cable provides the energy to make it happen.

Conclusion

Control cables and power cables serve fundamentally different roles in electrical systems. Control cables transmit low-voltage signals for automation and monitoring, featuring multiple conductors, shielding, and flexibility, while power cables deliver high-current electricity with fewer, larger conductors and thicker insulation. Understanding these differences ensures the right cable is chosen for the job, whether you’re powering a factory or controlling a smart home system, keeping operations safe and efficient.

Source: JianYunCable

Comments

Post a Comment