Understanding BV, BVR, and RV Cables

Table of Contents

Introduction

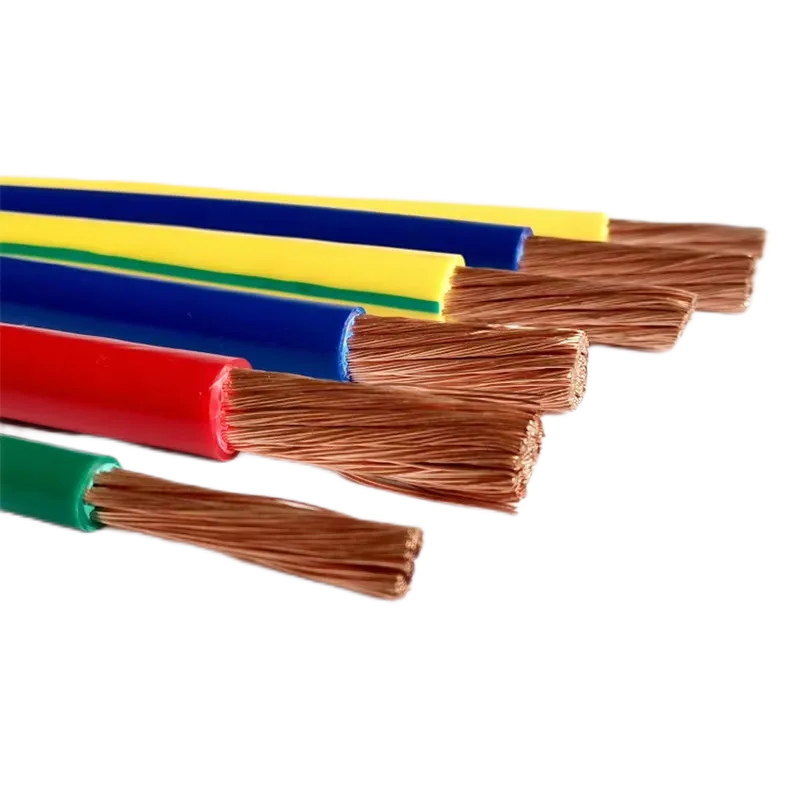

BV, BVR, and RV cables are commonly used in residential and industrial electrical installations. Understanding their differences is crucial for selecting the appropriate cable for specific applications.

BV Cable

BV (Building Wire) is a single-core, solid copper conductor cable insulated with PVC. It is known for its rigidity and is typically used in fixed wiring installations, such as concealed wiring in walls.

- Structure: Single solid copper core

- Insulation: PVC

- Voltage Rating: 450/750V

- Applications: Fixed wiring in residential and commercial buildings

BVR Cable

BVR (Flexible Building Wire) consists of multiple strands of copper wire, making it more flexible than BV cable. It is suitable for applications requiring frequent bending or movement.

- Structure: Multi-stranded copper core

- Insulation: PVC

- Voltage Rating: 450/750V

- Applications: Power distribution cabinets, electrical control systems, and equipment connections

RV Cable

RV (Flexible Connection Wire) is composed of numerous fine copper strands, offering superior flexibility. It is commonly used for internal wiring of electrical equipment and appliances.

- Structure: Multi-stranded fine copper wires

- Insulation: PVC

- Voltage Rating: 450/750V or 600/1000V

- Applications: Internal wiring of electrical equipment, control panels, and appliances

Comparative Analysis

| Feature | BV Cable | BVR Cable | RV Cable |

|---|---|---|---|

| Conductor Type | Single solid copper core | Multi-stranded copper core | Multi-stranded fine copper wires |

| Flexibility | Low | Medium | High |

| Applications | Fixed wiring | Power distribution, control systems | Internal equipment wiring |

| Voltage Rating | 450/750V | 450/750V | 450/750V or 600/1000V |

Selection Guidelines

When choosing between BV, BVR, and RV cables, consider the following factors:

- Flexibility Requirements: Use RV for high flexibility needs, BVR for moderate flexibility, and BV for fixed installations.

- Application Type: BV is ideal for concealed wiring; BVR suits control panels; RV is best for internal equipment connections.

- Voltage Requirements: Ensure the cable's voltage rating matches the system's requirements.

- Environmental Conditions: Consider factors like temperature, humidity, and exposure to chemicals when selecting insulation materials.

Conclusion

Understanding the distinct characteristics of BV, BVR, and RV cables enables informed decision-making for electrical installations. Selecting the appropriate cable type ensures safety, efficiency, and longevity of the electrical system.

- Source: JianYunCable

Comments

Post a Comment