Cross-Sectional Area of Wire: How to Calculate and Select Properly?

Choosing the right wire size is critical for safety, efficiency, and performance in any electrical project. The cross-sectional area (CSA) of a wire determines how much current it can safely carry without overheating. Get it wrong, and you risk voltage drops, fire hazards, or system failures. We’ve spent over 15 years in the cable industry helping engineers and installers select the perfect wire size — and today, we’re breaking it down step by step.

Table of Contents

- 1. What is Cross-Sectional Area (CSA) of a Wire?

- 2. How to Calculate Cross-Sectional Area

- 3. Quick Reference: mm² to AWG Conversion

- 4. How to Select the Right Wire Size (Step-by-Step)

- 5. Common Mistakes to Avoid

- 6. Cross-Sectional Area vs. Current Capacity: Real-World Example

- 7. Partner with a Trusted Cable Supplier

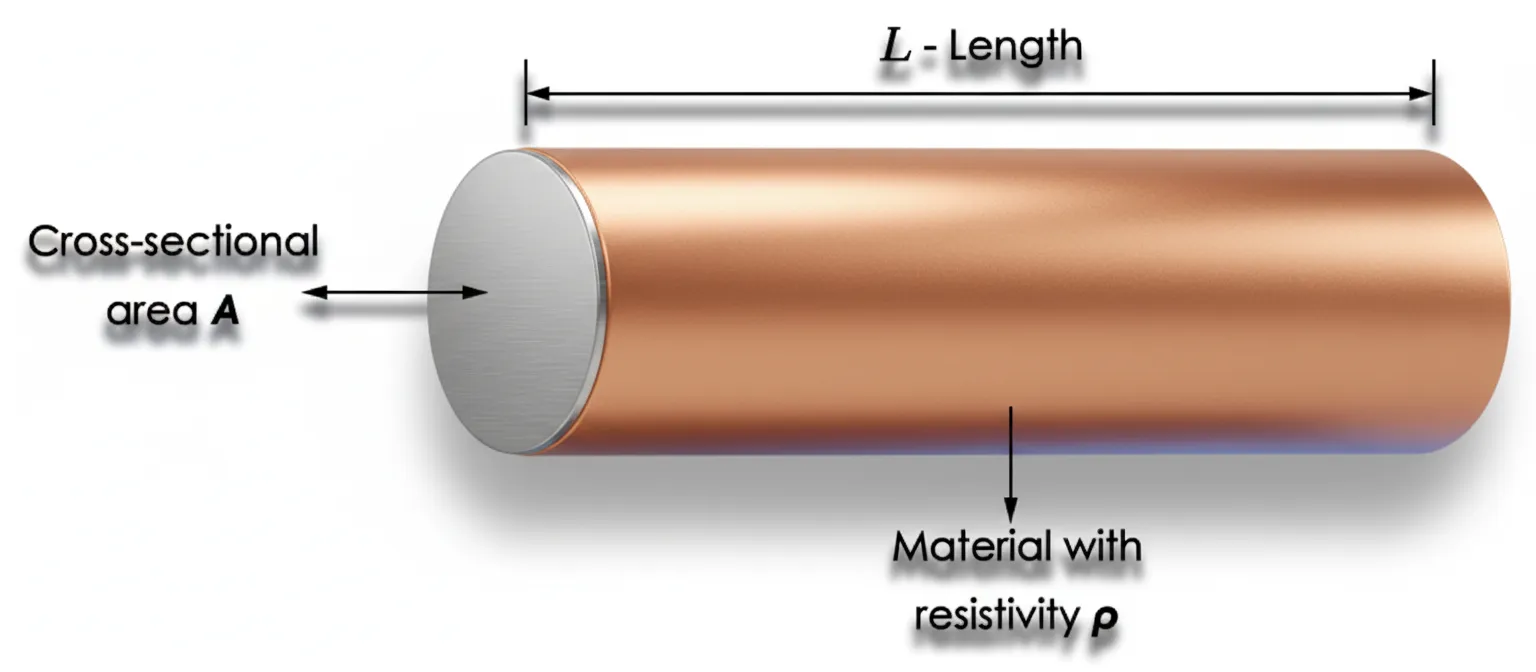

1. What is Cross-Sectional Area (CSA) of a Wire?

The cross-sectional area refers to the area of the conductor perpendicular to the current flow. For solid round wires, it’s simply the area of a circle. For stranded wires, it’s the total area of all strands combined.

- Measured in mm² (square millimeters) in most global standards (IEC, GB/T).

- AWG (American Wire Gauge) is common in North America — smaller number = larger CSA.

- Why it matters: Larger CSA = lower resistance = higher current capacity = less heat.

2. How to Calculate Cross-Sectional Area

Let’s keep it simple with the formulas you’ll actually use.

For Solid Round Wire:

CSA = π × (d/2)²

Where d = diameter of the conductor (in mm)

Example: A 3 mm diameter copper wire

CSA = 3.1416 × (3/2)² = 7.07 mm²

For Stranded Wire:

CSA = Number of strands × π × (strand diameter/2)²

Example: 19 strands of 0.8 mm wire

CSA per strand = 3.1416 × (0.8/2)² = 0.5027 mm²

Total CSA = 19 × 0.5027 = 9.55 mm²

3. Quick Reference: mm² to AWG Conversion

| mm² | AWG | Approx. Current (Copper, 3% drop) |

|---|---|---|

| 1.5 | 16 | 15 A |

| 2.5 | 14 | 20 A |

| 4 | 12 | 25 A |

| 6 | 10 | 32 A |

| 10 | 8 | 45 A |

| 16 | 6 | 60 A |

4. How to Select the Right Wire Size (Step-by-Step)

Follow this proven method to avoid undersizing or overspending:

- Calculate Load Current: I = P / (V × PF × √3 for 3-phase)

- Apply Derating Factors: Temperature, bundling, installation method (IEC 60364-5-52)

- Check Voltage Drop: ≤3% for power, ≤5% for lighting

- Verify Short-Circuit Withstand: Cable must handle fault current for 1 second

- Confirm Mechanical Strength: Especially for overhead or direct burial

5. Common Mistakes to Avoid

- ⚠️ Using AWG tables without derating for high ambient temps

- ⚠️ Ignoring voltage drop on long runs (>50m)

- ⚠️ Mixing copper and aluminum without proper joints

- ⚠️ Oversizing “just to be safe” — wastes money and space

6. Cross-Sectional Area vs. Current Capacity: Real-World Example

Project: 30 kW motor, 400V, 50m cable run, 40°C ambient

→ I = 30,000 / (400 × 0.85 × 1.732) ≈ 51 A

→ With derating (0.87), need ~59 A capacity

→ Select 16 mm² copper (rated 76 A in conduit)

7. Partner with a Trusted Cable Supplier

Need help selecting the perfect wire size? Henan Province Jianyun Cable Co., Ltd. offers TUV-certified copper and aluminum cables in all standard CSA sizes — from 1.5 mm² to 400 mm².

✅ Free sizing calculations

✅ Fast global shipping

✅ Custom lengths and packaging

Contact us today for a quote or technical support!

Comments

Post a Comment