Inside a High Voltage Cable Factory: From Design to Production

Table of Contents

- 1. What is a High Voltage Cable?

- 2. Step-by-Step Manufacturing Process

- 3. Key Materials Used

- 4. Quality Control & Testing

- 5. Inside Jianyun Cable’s High Voltage Line

1. What is a High Voltage Cable?

High voltage cables are used to transmit electrical energy over long distances at voltages typically above 35 kV. These cables are essential in power transmission networks, industrial infrastructure, and large renewable energy projects.

2. Step-by-Step Manufacturing Process

The production of high voltage cables involves multiple sophisticated stages:

| Stage | Description |

|---|---|

| 1. Design & Engineering | Technical team defines voltage rating, insulation type, conductor size, and application needs. |

| 2. Conductor Production | Copper or aluminum rods are drawn, stranded, and shaped into precise conductors. |

| 3. Extrusion | Insulating materials such as XLPE are applied over the conductor using high-temperature extrusion lines. |

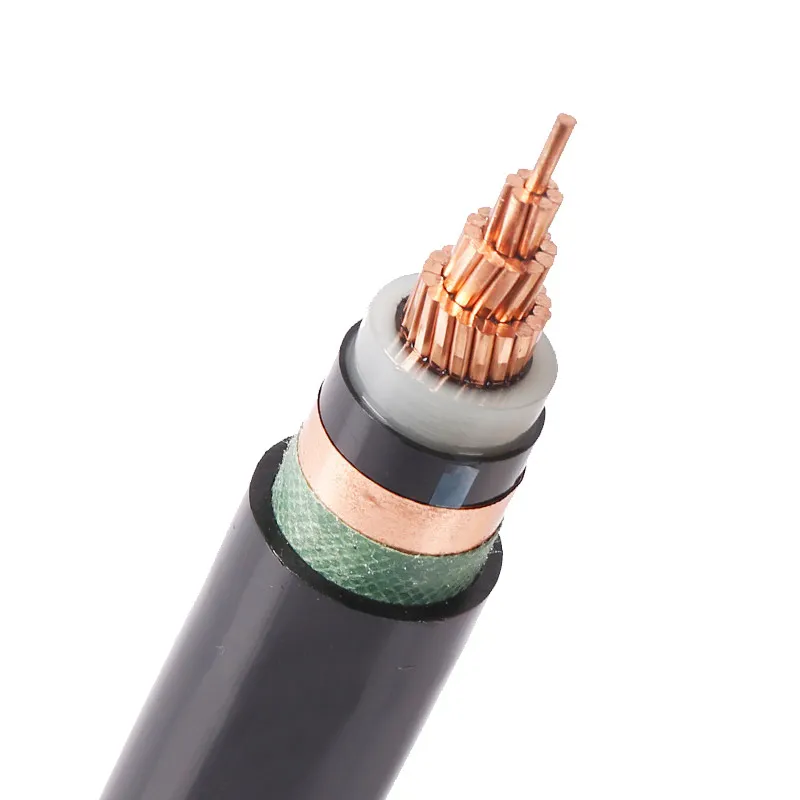

| 4. Shielding & Armoring | Metallic or semi-conductive layers are added to protect against electromagnetic interference and mechanical damage. |

| 5. Jacketing | The final outer jacket is applied to resist moisture, UV, fire, or chemicals, depending on the application. |

| 6. Cable Testing | Each cable is tested under high voltage and other stress conditions to ensure safety and performance. |

3. Key Materials Used

- Conductors: Copper or aluminum

- Insulation: XLPE (cross-linked polyethylene), EPR

- Shielding: Copper tape, aluminum foil, or semi-conductive layers

- Armor: Steel wire or tape for mechanical protection

- Jacket: PVC, PE, LSZH (Low Smoke Zero Halogen)

4. Quality Control & Testing

Quality is paramount in high voltage cable manufacturing. The factory uses advanced testing equipment to perform:

- High Voltage Withstand Tests

- Partial Discharge Tests

- Tensile Strength and Elongation Tests

- Thermal Aging and Flame Retardancy Tests

- Electrical Resistance and Conductivity Checks

5. Inside Jianyun Cable’s High Voltage Line

Henan Jianyun Cable Co., Ltd. operates a state-of-the-art high voltage cable production facility equipped with intelligent extrusion lines, precision stranding machines, and real-time online inspection systems. Established in 2009, Jianyun Cable has built a reputation for delivering reliable and high-performance cables to power utilities and global infrastructure projects.

With a complete quality assurance process from raw material selection to final inspection, Jianyun ensures that every meter of high voltage cable meets both national and international standards. The factory also provides custom solutions for large-scale energy projects, including wind farms, substations, and grid upgrades.

Source: JianYunCable.

Comments

Post a Comment