Aging Life Assessment of Eco-Friendly Polypropylene Insulation for Medium Voltage Power Cables

Introduction

As energy demands increase globally and environmental regulations become more stringent, the power cable industry is shifting towards sustainable materials. Among these, thermoplastic polypropylene (PP) has gained significant attention as a next-generation insulation material for medium voltage cables. Its favorable characteristics—such as recyclability, high dielectric strength, low dielectric loss, and excellent thermal resistance—make it a strong candidate to replace traditional cross-linked polyethylene (XLPE).

However, like all polymers, polypropylene faces challenges related to aging and insulation degradation under electrical and thermal stress. Accurately assessing the aging life of PP insulation is crucial for ensuring long-term cable reliability and safety. This article summarizes a comprehensive study that investigates the thermal-oxidative and electrical aging behavior of two types of polypropylene insulation materials: PP6 and PPS.

1. Experimental Materials and Methods

Materials

Three types of PP insulation samples were tested:

PP6 (a standard polypropylene formulation)

PPS (a modified polypropylene with antioxidant additives)

PPS Cable (extruded cable insulation based on PPS)

Each material underwent both thermal-oxidative and electrical aging tests to simulate real-world cable operation environments.

Thermal Aging Test

Specimens were dried and molded into uniform thin films. The oxidation induction time (OIT) was measured at six different temperatures ranging from 180°C to 230°C using differential scanning calorimetry (DSC).

Electrical Aging Test

Samples were prepared using a compression molding method and shaped into circular membranes. Aging behavior was evaluated under various electric field conditions using three accelerated testing protocols:

Constant voltage method

Stepwise voltage boosting method

Simplified approximation method

2. Thermal-Oxidative Aging Behavior

OIT Analysis and Lifetime Prediction

The study showed that OIT values of all three materials decreased as test temperature increased, indicating a reduction in thermal stability with rising temperature. Based on these results, a linear regression analysis was used to model the aging life at different operating temperatures.

| Temperature (°C) | OIT (min) for PPS Cable |

|---|---|

| 200 | 129.92 |

| 210 | 55.20 |

| 220 | 13.47 |

| 230 | 4.74 |

From this data, the thermal aging lifetime was extrapolated. At an operational temperature of 90°C, the estimated service life of:

PP6 is approximately 40 years

PPS is approximately 69 years

This indicates that PPS has better long-term thermal stability due to its enhanced formulation and antioxidant system.

3. Electrical Aging Analysis

Aging Lifetime Index (n)

The electrical aging life of insulation materials is characterized by a parameter known as the aging life index (n), which reflects how rapidly the material deteriorates under increasing electric field stress.

The study evaluated the aging index using three methodologies:

Constant voltage method

Stepwise boosting accumulation method

Simplified approximation method

The results are summarized in the following table:

| Method | PP6 (n range) | PPS (n range) |

|---|---|---|

| Constant voltage | 10.07 – 16.35 | 12.84 – 14.68 |

| Stepwise boosting | 12.65 – 16.68 | 14.07 – 17.29 |

| Simplified approximation | 12.50 – 13.20 | 6.70 – 13.40 |

The stepwise boosting method yielded the most stable and reliable results due to its minimized data dispersion.

Lifetime Modeling

Two estimation techniques were used to model electrical lifetime:

Linear regression with fixed index

Least squares estimation (more accurate)

The following results were obtained using the least squares method:

| Parameter | PP6 | PPS |

|---|---|---|

| Aging index (n) | 13.39 | 14.02 |

| Regression coefficient | 0.96 | 0.97 |

| Estimated lifetime | Valid above 40 years under standard stress |

These results suggest both materials can operate effectively for more than 40 years under field strength up to 19 kV/mm and temperatures below 90°C.

4. Comprehensive Lifetime Prediction

A combined analysis of thermal and electrical aging data was performed to assess the practical service life of PP insulation materials under multi-stress operating conditions.

| Temperature (°C) | Electric Field (kV/mm) | PP6 Lifetime (years) | PPS Lifetime (years) | Dominant Aging Factor |

|---|---|---|---|---|

| 80 | 18 | 160 | 199 | Electrical |

| 80 | 19 | 77 | 93 | Electrical |

| 80 | 20 | 39 | 45 | Electrical |

| 85 | 18 | 88 | 157 | Thermal |

| 85 | 19 | 77 | 93 | Electrical |

| 85 | 20 | 39 | 45 | Electrical |

| 90 | 18 | 40 | 69 | Thermal |

| 90 | 19 | 40 | 69 | Thermal |

| 90 | 20 | 39 | 45 | Electrical |

It is clear that:

At lower temperatures, electrical stress dominates insulation aging.

At higher temperatures and moderate field strength, thermal aging becomes more critical.

5. Morphological Analysis and Aging Mechanism

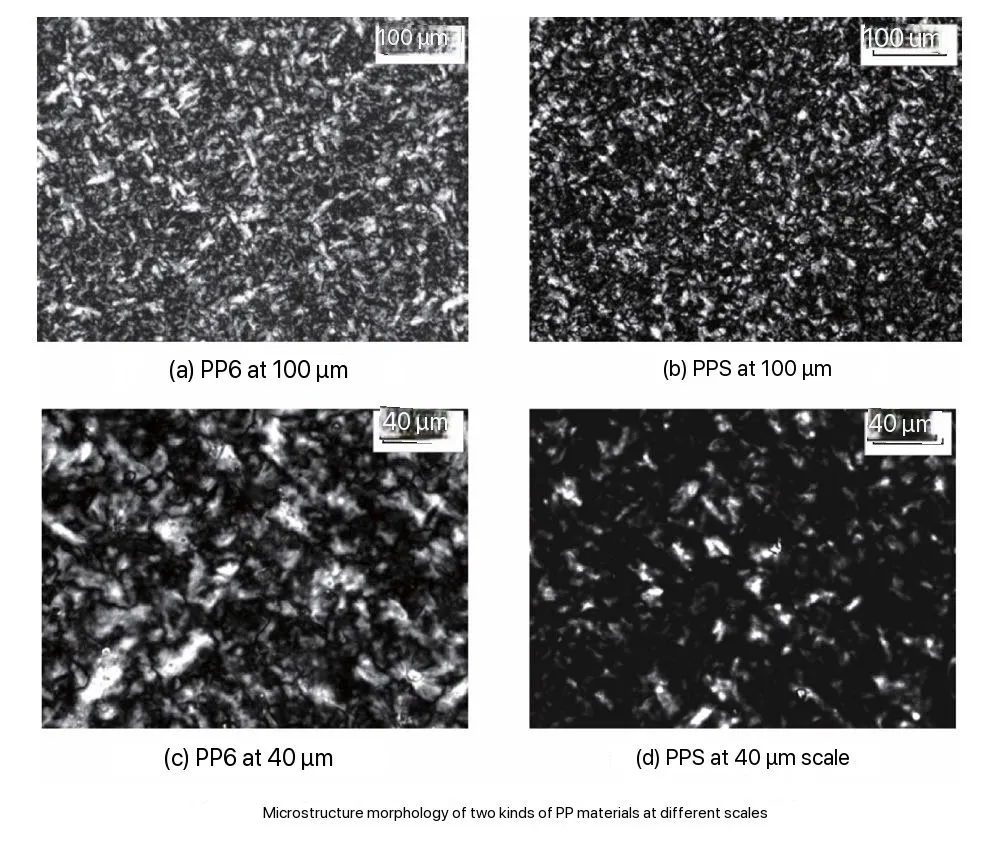

Microscopic examination of PP6 and PPS revealed structural differences that explain their aging behaviors:

PP6 has larger crystalline domains and thicker lamellae, providing better short-term performance under high electric fields but leading to faster degradation under long-term stress.

PPS has smaller, denser crystalline structures with more amorphous regions, slowing the formation of microvoids and enhancing long-term durability at low field strengths.

This morphological insight confirms that electrical aging is closely related to polymer crystallization characteristics.

6. Conclusion

Both PP6 and PPS exhibit strong aging resistance, with predicted service lives exceeding 40 years under standard medium-voltage cable operating conditions.

The thermal and electrical lifetime models derived through accelerated testing methods are reliable and provide a theoretical foundation for insulation design.

PPS outperforms PP6 in long-term low-stress environments due to its optimized crystallization behavior, while PP6 demonstrates superior short-term resistance under high stress.

The study confirms that polypropylene is a viable and eco-friendly alternative to traditional cable insulation materials for future power cable systems.

Keywords

Polypropylene Cable Insulation

Electrical Aging

Thermal Oxidation

Lifetime Prediction

Medium Voltage Power Cables

Aging Life Index

Polymer Morphology

References

Liu Xiongjun, Han Xiao, Xi Qianyi, et al. (2024). Research and Determination of Aging Life for New Environmentally Friendly Polypropylene Insulation Materials. Wire & Cable, No. 4, 2024. DOI: 10.16105/j.dxdl.1672-6901.202404001

GB/T Standards on Polymer Aging Tests

IEEE Transactions on Dielectrics and Electrical Insulation.Source: JianYunCable

Comments

Post a Comment